- ball

- Gate valve

- butterfly valve

- Regulating valve

- Cut-off valve

- Globe valve

- Check valve

- Knife Gate Valve

- Safety valve

- Pressure relief valve

- Drain valve

- Plug valve

- Diaphragm valve

- Discharge valve

- Exhaust valve

- Filter

- Solenoid valve

- Needle valve

- Plunger valve

- Copper valve

- Compensator

- Hydraulic control valve

- Electric two way valve

- Vacuum valve

- Thermal insulation valve

- Flame arrester

- Breathing valve

- Balance valve

- Sludge discharge valve

- Ammonia valve

- Metallurgical valves

- Fluorine valve

- Low temperature valve

- Power station valve

- Natural gas valves

- Other valves

- Inlet valve

- Import actuator

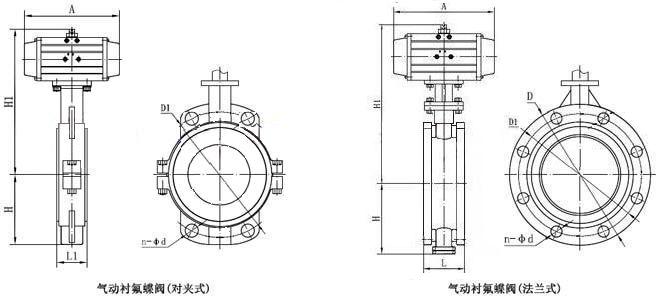

Pneumatic lining butterfly valve

- sell:021-32051999

- sell:021-32050777

- fax:021-66099555

Details

- Product Introduction

- Service Promise

- Ordering Process

Pneumatic fluorine-lined butterfly valve (also known as corrosion-resistant pneumatic butterfly valve) is composed of pneumatic piston actuator and tetrafluoro-sealed butterfly valve. Fluorine-lined pneumatic butterfly valve is a kind of high molecular material with thick lining technology on the over-flow parts, valve body, butterfly plate and valve stem. It has excellent corrosion resistance and can be applied to any concentration of acid, alkali, salt and oxidant, reducing agent, organic solvent, etc. Medium, pneumatic fluorine-lined butterfly valve is an ideal product for intercepting and regulating equipment in gas, liquid and semi-fluid pipelines and containers of chemical, petroleum, pharmaceutical, food, steel smelting, paper making, hydropower and other systems. Fully lined polytetrafluoroethylene (F4) and polyperfluoroethylene propylene (F46) fluoroplastic lined valves have the advantages of corrosion resistance, leak-free, long service life and so on. Corrosion-resistant pneumatic butterfly valve is suitable for concentrated sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, Aqua regia, various organic acids, strong acids, oxidizing media or high-temperature olefinic acid, high-temperature concentrated acetic acid, acid-base alternation and a variety of organic solvents and other strong corrosive media.

Main features of pneumatic lining butterfly valve

1, small size, light weight, easy operation, easy installation and maintenance.

2, good sealing performance, reliable zero leakage and long service life.

3, the flow characteristics tend to be straight, and the regulation performance is the best.

4, simple structure, fast switching, 90 degree rotary opening and closing.

5, can replace gate valve, stop valve, plug valve, hose valve and diaphragm valve and other valves.

6. The pneumatic and electric devices can be configured to meet the needs of remote control and program control.

7, replacement of parts lining material can be applied to all kinds of media.

Main technical parameters of pneumatic lining butterfly valve

valve body

type of body | Straight through casting butterfly valve |

Nominal path | DN50~1000mm |

Nominal pressure | PN1.0、1.6 MPa |

Flanges standard | JIS B220、JB/T79、ANSI B16.5-1981、GB/T9113、HG20594-97、HG20618-97等 |

Connection form | Flanged、Pair clip |

Valve cover form | One in one |

Capping type | Gland pressing type |

Seal filler | V PTFE packing and flexible graphite filler |

Valve plate form | Vertical plate type (butterfly shaped) |

Flow characteristics | linear |

Actuator type | GT series, ST series, AT series and AW series single and double acting pneumatic actuators |

Gas supply pressure | 400~700KPa |

air connection | G1/4"、G1/8"、G3/8"、G1/2" |

ambient temperature | -30~+70℃ |

Form of action | Single acting actuator: B: when the gas is lost, the valve position is opened (FO); the gas opening type (K) is the valve position (FC) when the gas is lost.

Double-acting actuator: air-closed type (B) - valve position retention (FL) during degassing; air-open type (K) - valve position retention (FL) single-acting double-acting pneumatic actuator during degassing |

Appendable appendage | Locator, solenoid valve, air filter pressure reducer, retaining valve, stroke switch, valve position conveyor, handwheel mechanism, etc. |

Note: for detailed actuator parameters, please go to the pneumatic actuator page for inspection.

Material for main parts of pneumatic lining butterfly valve

Body and base | Ductile cast steel, cast steel, stainless steel, fluorine lined |

Disc | Gray cast iron, spheroidal graphite cast steel, cast steel, stainless steel and special materials, fully lined with fluorine. |

Seal ring | All kinds of rubber and polytetrafluoroethylene |

Stem | 2Cr13, stainless steel, fully lined fluorine |

filler | V PTFE packing and flexible graphite filler |

Return difference | Positioner: less than full stroke.2% |

Return difference | Positioner: less than full stroke.±2% |

Leakage amount L / h | Comply with ANSI B16.104 IV level standard |

Adjustable range R | 50:1 |

Nominal diameter DN (mm) | 50-1800 | |||

Nominal pressure | PN(MPa) | 0.6 | 1.0 | 1.6 |

Test pressure | strength test | 0.9 | 1.5 | 2.4 |

Seal test | 0.66 | 1.1 | 1.76 | |

Low pressure airtightness test | 0.6 | 0.6 | 0.6 | |

Applicable medium | Air, water, sewage, steam, gas, oil, etc. | |||

Nominal diameter DN (mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | |

L | 90 | 90 | 100 | 115 | 130 | 140 | 150 | 250 | 270 | 290 | 310 | 330 | 350 | 390 | 430 | 470 | 500 | 550 | |

L1 | 43 | 46 | 49 | 56 | 64 | 70 | 71 | 76 | 83 | 92 | 102 | 113 | 127 | 154 | 165 | 190 | 203 | 216 | |

H | Flanged | 63 | 70 | 83 | 105 | 115 | 137 | 164 | 206 | 230 | 248 | 289 | 320 | 343 | 413 | 478 | 525 | 585 | 640 |

Pair clip | 63 | 70 | 83 | 105 | 115 | 137 | 164 | 206 | 230 | 248 | 289 | 320 | 343 | 413 | 478 | 525 | 585 | 640 | |

n-φd | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | 16-26 | 16-30 | 20-30 | 20-33 | 20-36 | 24-36 | 24-39 | 28-39 | 28-42 | |

H1 | Depending on the executing agency. | ||||||||||||||||||

A | Depending on the torque required by the valve, the configuration models are different and the dimensions are different. | ||||||||||||||||||

D | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 640 | 715 | 840 | 910 | 1025 | 1125 | 1255 | |

D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | 1050 | 1170 | |

The best quality, first-class service Qigao creates more value for you!

"Qigao Valve" expects to continuously improve service quality and strive for excellence. "Sincere service" is the eternal theme of "Qigao". "Qigao" strictly followsIS09001-2000 Quality system certification requirements, strict quality control, responsibility to people, to ensure the healthy operation of production, sales and service. Strengthen communication with users and provide quality products to our customers with perfection and perfect service. Hereby our factory makes the following commitments:

Product Standards:

Products in strict accordance with ChinaGB、HG Standard and USAPISuch as standard design, manufacturing, acceptance. The hardness of the sealing surface meets the requirements of the state and the width exceeds the national standard.

pre-sale service:

Product introduction, technical exchange, non-standard product design, troubleshooting。

Sale service:

A trustworthy contract guarantees timely delivery and keeps in touch with customers. For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" brand product quality period is from the factory12In the month, the implementation of the "three guarantees" service (return, replacement, warranty).

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions, so as to further improve product quality.

3、Respond quickly to the quality of user complaints, after-sales service personnel rushed to the scene in 24-36 hours (48 hours outside the province).

4、For after-sales service, users are required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of Qigao.

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

a、Structure length;

b、Connection Type;

c、Nominal diameter, full diameter, reduced diameter, pipe size;

d、Operating medium and temperature, pressure range;

e、Tests, inspection standards and other requirements

2、The factory can configure various types of driving devices according to customer's specific requirements.。

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

4、For futures and order customers, please call us in advance to tell the required valve model, specification, quantity, delivery time and location, and timely transfer to the factory account according to the total 30% deposit or full payment. The rest of the payment is pending. Import before shipment to arrange delivery in time.

Order Process:

1、Customer purchase list fax to021-33872143,Or call us 021-33872141

2、Receive customer purchase list, provide valve model selection and quotation (price list)。

3、Specific agreement: delivery date, special requirements, etc.。

download Google:

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

|

|||||

|

|||||

2、The factory can configure various types of driving devices according to customer's specific requirements.。

|

|||||

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

|

|||||

4、For futures and order customers, please call us first to tell the required valve model, specifications, quantity, delivery time and location, and press the total30%The deposit or full payment will be remitted to our factory account in time., The rest of the payment will be remitted before shipment to arrange delivery in time.。

|

Sale service:

Trustworthy contract, guarantee timely delivery, keep in touch with customers at any time。

For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" product quality period is from the factory12Month, practice“Three packs”Service (return, replacement, warranty)。

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions.,

In order to further improve product quality。

3、Respond quickly to the quality of user complaints, after-sales service personnel24-36Hours (outside the province48Hour) rushed to the scene。

4、For after-sales service, the user is required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of “Qigao”.。

statement |

|