- ball

- Gate valve

- butterfly valve

- Regulating valve

- Cut-off valve

- Globe valve

- Check valve

- Knife Gate Valve

- Safety valve

- Pressure relief valve

- Drain valve

- Plug valve

- Diaphragm valve

- Discharge valve

- Exhaust valve

- Filter

- Solenoid valve

- Needle valve

- Plunger valve

- Copper valve

- Compensator

- Hydraulic control valve

- Electric two way valve

- Vacuum valve

- Thermal insulation valve

- Flame arrester

- Breathing valve

- Balance valve

- Sludge discharge valve

- Ammonia valve

- Metallurgical valves

- Fluorine valve

- Low temperature valve

- Power station valve

- Natural gas valves

- Other valves

- Inlet valve

- Import actuator

J961Y Power Station Globe Valve

- sell:021-32051999

- sell:021-32050777

- fax:021-66099555

Details

- Product Introduction

- Service Promise

- Ordering Process

J961Y electric welding power station stop valve

1. body and bonnet connection form: PN10-64 uses bolted bonnet; PN64-320 uses self pressurized sealed bonnet.

2. Stem nut: In general, the stem nut material ASTM A439 D2, and can be used according to user requirements copper alloy and other materials, for large-caliber globe valves, installed with rolling bearings, can effectively reduce the opening moment of the globe valve so that the valve can be easily switched on and off.

3. stem design: the whole forging process is made, and the minimum diameter is determined according to the standard requirements.

4. Cover gasket type: PN10-64 globe valve with stainless steel graphite winding gasket; PN100 globe valve with stainless steel graphite winding gasket can also be used metal ring gasket; PN160 globe valve can be used metal ring gasket, PN320 globe valve with self-pressure sealing metal ring.

5. structural features of the cut-off valve: Bolted valve cover, bright pole bracket and lifting valve stem metal cover.

6. Upper Seal Design: All globe valves provided by our company have inverted seal design. Usually, carbon steel globe valves are designed with separate inverted seal structure. The inverted seal surface of stainless steel globe valves is very reliable. Although there is a reverse seal in the standard API600, this is not the basis for changing the packing under pressure.

7. Filling Seal: Formed flexible graphite is usually used as filling material, and PTFE or composite filling material can be provided according to user's needs. The surface roughness of packing and packing box is 3.2u m, which can ensure the close contact between the stem and packing but can rotate freely. The precision machined sealing surface roughness of the stem is 0.8u m, which can ensure the reliable sealing of the stem.

8. Seat: Carbon steel globe valve seat is usually made of forged steel. Seat sealing surface can be sprayed with cemented carbide according to customer's requirements. NPS < 10 cut-off uses separated threaded screw-in seats, which can also be provided if customer needs to weld seating structure; NPS < 12 cut-off valve seat adopts welded seating structure; stainless steel globe valve seat 1 Use the whole body or weld the cemented carbide on the body and directly process the valve seat. Stainless steel globe valve seats are also available with separate threaded screw-in and welded seats if required.

Main performance and application scope

產(chǎn)品型號(hào) | 公稱壓力 | 試驗(yàn)壓力 | 工作壓力 | 工作溫度(℃) | 適用介質(zhì) | |||

殼體強(qiáng)度 | 密封 | P54 | P55 | P57 | ||||

J61H/Y-100 | 10 | 15 | 11 | ≤450 | 水、蒸汽、油品 | |||

J61H/Y-200 | 20 | 30 | 22 | |||||

J61H/Y-250 | 25 | 38 | 28 | |||||

J61H/Y-320 | 32 | 48 | 36 | |||||

J61Y-P54/100V | 30 | 22 | 10 | ≤540 | 蒸 汽 | |||

J61Y-P54/140V | 38 | 28 | 14 | |||||

J61Y-P54/170V | 48 | 36 | 17 | 10 | ||||

J61Y-P55/100V | 38 | 28 | 14 | ≤555 | ||||

J61Y-P55/140V | 48 | 36 | 17 | |||||

J61Y-P55/170V | 53 | 39 | 10 | |||||

J61Y-P57/100V | 48 | 36 | 14 | ≤570 | ||||

J61Y-P57/140V | 55 | 40 | 17 | |||||

J61Y-P57/170V | 60 | 44 | ||||||

零件名稱 | 閥體 | 閥蓋 | 閥桿 | 閥瓣 | 密封面 | 填料 | 閥桿螺母 | 手輪 | 緊固體 |

J61H型 | 25 WCB | 25 40Cr | 鉻不銹鋼 鉻鉬鋁鋼化 | 鉻不銹鋼 | 鉻不銹鋼 | 柔性石墨 | 鋁青銅 | 可鍛鑄鐵 | 優(yōu)良碳鋼鉬鋼 |

J61Y型 | 25 WCB | 25 40Cr | 鉻不銹鋼 鉻鉬鋁鋼化 | 25 | 硬質(zhì)合金 | 柔性石墨 | 鋁青銅 | 可鍛鑄鐵 | 優(yōu)良碳鋼鉻鉬鋼 |

J61 Y-P54型 | ZG20CrMolV 12CrlMolV | 12C r1MolV | 20CrMol V 25CrlMolV | 12CrlMolV | 硬質(zhì)合金 | 柔性石墨 | 鋁青銅 | 可鍛鑄鐵 | 鉻鉬鋼 |

J61 Y-P55型 | ZG25CrMol V12CrlMolV | 12C r1MolV | 20CrMol V 25CrlMolV | 12C r1MolV | 硬質(zhì)合金 | 柔性石墨 | 鋁青銅 | 可鍛鑄鐵 | 鉻鉬鋼 |

J61 Y-P57型 | ZGl5CrMolV 12CrlMolV | 12CrlMolV | 20CrMol V25CrlMolV | 12CrlMolV | 硬質(zhì)合金 | 柔性石墨 | 鋁青銅 | 可鍛鑄鐵 | 鉻鉬鋼 |

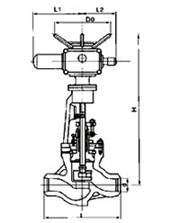

構(gòu)圖.jpg)

公稱通徑DN | 主要外形尺寸和連接尺寸(mm) | 重量(kg) | ||||||

L | D1 | D2 | D3 | α | H | D0 | ||

J61(H.Y)-25、40、64、100、200、250、320 J61Y-P54/100V、P54/140V、P54/170V | ||||||||

10 | 120 | 12 | 25 | 40° | 185 | 140 | 2.8 | |

15 | 170 | 17 | 36 | 40° | 247 | 200 | 7.5 | |

20 | 170 | 22 | 42 | 40° | 248 | 200 | 9 | |

25 | 170 | 26 | 42 | 40° | 248 | 240 | 9.5 | |

32 | 170 | 31 | 44 | 40° | 248.5 | 280 | 15 | |

50① | 250 | 50 | 82 | 32° | 450 | 320 | 60 | |

50② | 350 | 50 | 82 | 32° | 450 | 320 | 64 | |

65 | 430 | 69 | 100 | 110 | 32° | 669 | 400 | 74 |

80 | 470 | 84 | 108 | 130 | 32° | 669 | 450 | 112.5 |

100 | 560 | 107 | 144 | 165 | 32° | 755 | 500 | 178.5 |

Note: DN50 is two models.

J61Y-P55/100V, P55/140V, P55/170V J61Y-P57/100V, P57/140V, P57/170V

10 | 120 | 12 | 28 | 40° | 189 | 140 | 3 | |

15 | 170 | 17 | 40 | 40° | 250 | 200 | 9 | |

20 | 170 | 22 | 46 | 40° | 252 | 200 | 11 | |

25 | 170 | 26 | 46 | 40° | 254 | 240 | 13 | |

32 | 170 | 31 | 49 | 40° | 254 | 280 | 17 | |

50① | 250 | 50 | 90 | 32° | 453 | 320 | 68 | |

50② | 350 | 50 | 90 | 32° | 455 | 320 | 72 | |

65 | 430 | 69 | 104 | 115 | 32° | 630 | 400 | 83 |

80 | 470 | 84 | 110 | 140 | 32° | 672 | 450 | 118 |

100 | 560 | 17 | 148 | 170 | 32° | 761 | 500 | 165 |

The best quality, first-class service Qigao creates more value for you!

"Qigao Valve" expects to continuously improve service quality and strive for excellence. "Sincere service" is the eternal theme of "Qigao". "Qigao" strictly followsIS09001-2000 Quality system certification requirements, strict quality control, responsibility to people, to ensure the healthy operation of production, sales and service. Strengthen communication with users and provide quality products to our customers with perfection and perfect service. Hereby our factory makes the following commitments:

Product Standards:

Products in strict accordance with ChinaGB、HG Standard and USAPISuch as standard design, manufacturing, acceptance. The hardness of the sealing surface meets the requirements of the state and the width exceeds the national standard.

pre-sale service:

Product introduction, technical exchange, non-standard product design, troubleshooting。

Sale service:

A trustworthy contract guarantees timely delivery and keeps in touch with customers. For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" brand product quality period is from the factory12In the month, the implementation of the "three guarantees" service (return, replacement, warranty).

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions, so as to further improve product quality.

3、Respond quickly to the quality of user complaints, after-sales service personnel rushed to the scene in 24-36 hours (48 hours outside the province).

4、For after-sales service, users are required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of Qigao.

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

a、Structure length;

b、Connection Type;

c、Nominal diameter, full diameter, reduced diameter, pipe size;

d、Operating medium and temperature, pressure range;

e、Tests, inspection standards and other requirements

2、The factory can configure various types of driving devices according to customer's specific requirements.。

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

4、For futures and order customers, please call us in advance to tell the required valve model, specification, quantity, delivery time and location, and timely transfer to the factory account according to the total 30% deposit or full payment. The rest of the payment is pending. Import before shipment to arrange delivery in time.

Order Process:

1、Customer purchase list fax to021-33872143,Or call us 021-33872141

2、Receive customer purchase list, provide valve model selection and quotation (price list)。

3、Specific agreement: delivery date, special requirements, etc.。

download Google:

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

|

|||||

|

|||||

2、The factory can configure various types of driving devices according to customer's specific requirements.。

|

|||||

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

|

|||||

4、For futures and order customers, please call us first to tell the required valve model, specifications, quantity, delivery time and location, and press the total30%The deposit or full payment will be remitted to our factory account in time., The rest of the payment will be remitted before shipment to arrange delivery in time.。

|

Sale service:

Trustworthy contract, guarantee timely delivery, keep in touch with customers at any time。

For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" product quality period is from the factory12Month, practice“Three packs”Service (return, replacement, warranty)。

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions.,

In order to further improve product quality。

3、Respond quickly to the quality of user complaints, after-sales service personnel24-36Hours (outside the province48Hour) rushed to the scene。

4、For after-sales service, the user is required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of “Qigao”.。

statement |

|